No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

30 kV ESD Guns

Viewed products

-

Teseq NSG 439 ESD...

Intended for use in robotic...

Best sellers

-

Schaffner / Teseq NSG 435 ESD Simulator for IEC 61000-4-2

Programmable discharge voltage 200 V to 16.5 kV Stabilized charging...

$590.00 -

ESDGuns.com GRC Series Ground Cable w/ 470k Ohm Resistors for ESD Voltage Bleeding

Ideal for voltage bleeding to Ground Plane during Indirect ESD Immunity...

$199.00 -

Rent Keytek Minizap MZ-15/EC 15kV ESD Simulator Gun

Rentals Ship Immediately Purchase Options See: Used Keytek Minizap ESD...

$495.00 -

ESD Guns IF Insulating Foil for ESD Compliance Testing

Suitable for EN/IEC 61000-4-2 ESD immunity compliance testing...

$197.00 -

Teseq / Schaffner INA 405 Ni-Mh Battery Pack Refurbishment for NSG 435 ESD Gun

ESD Guns can refurbish your existing INA 405 battery pack. Expected...

$275.00 -

Haefely ONYX 16 kV ESD Generator Gun

Rental Package IncludesAir and Contact Discharge Tips Output...

$595.00 -

Teseq NSG 437 Electrostatic Discharge (ESD) Simulator Gun for GR-1089 & IEC 61000-4-2

Air- and contact-discharge to 30 kV Color touch panel control Advanced...

$895.00 -

3ctest EDS 20H Hand-held 20kV Electrostatic Discharge ESD Simulator

Air- and Contact- Discharge: 1000 Volts - 20kV ±5% Rise time: 0.6-1ns RC...

$476.00

Teseq NSG 439 ESD Simulator

New

- Intended for use in robotic applications

- Equivalent to the Teseq NSG 438 ESD Simulator

- Used system suitable for field use and economically priced

More info

ESD Guns has acquired an NSG 439 and is offering it at a substantially discounted rate from MSRP. The chassis of the discharge pistol is designed for a mounted use on a robot, but is equivalent to the Teseq NSG 438 in every other way.

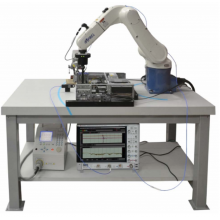

This will be suitable for robotic applications, or track mount applications performing vertical air discharge. Alternatively, a handle can be fabricated and can be used as a pistol comparable to it's NSG 438 sister model.

Teseq NSG 439 Overview:

Today’s growing trend towards miniaturizing and more comprehensive product standards means that ESD testing is now required not only for operating controls, but also for any associated peripheral devices such as sensors, actuators and controllers. Many of these devices have multi-pin connectors with high pin counts. In order to meet space restrictions, these pins are often arranged close together.

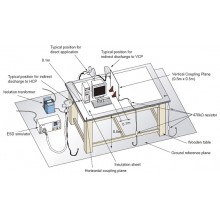

However, conventional air-discharge testing of these closely spaced pins is problematic because the airdischarge arc may jump to an adjacent pin instead of the pin intended for test. With an innovative robotic air-discharge adapter accessory, Teseq provides a tool which will prevent unintentional discharge paths. Furthermore, the approach speed, which is crucial for reliable air-discharge testing, can be programmed as a constant.

ESD testing of connectors often requires that each individual pin is tested for an extensive range of conditions including multiple discharges, polarities, voltage settings, and even R/C networks. Connector testing can take many hours or even days of monotonous, precise effort to complete. As a result, when this testing is done manually it is prone to errors. The advantage of robotic testing is that these procedures can be automated and precisely executed, ensuring a level of repeatability that cannot be achieved with manual testing.

Teseq NSG 439 Features:

- Air- and contact-discharge to 30 kV

- Battery tested to 30’000 discharges at 30 kV

- Standard Discharge Networks for IEC 61000-4-2, RTCA/DO-160 and Mil-STD-461G CS 118

- Custom Discharge Networks for ISO 10605

- Touch panel control

- Advanced voltage-hold feature

- Activity log

- Compliant with a huge range of OEM and international standards

- Built-in ISO self-calibration procedure

- Easily and quickly interchangeable discharge networks

- Selectable discharge detector

Accessories Included with the Teseq NSG 439:

- Carrying case with:

- Discharge pistol

- High voltage base unit with built-in battery pack, mains adapter and battery charging unit (100 to 250 VAC)

- INA4380 Discharge network 150 pF/330 Ω for IEC 61000-4-2

- Air- and contact-discharge tips

- Grounding cable

- User manual (linked below)